Ironline

Compressions

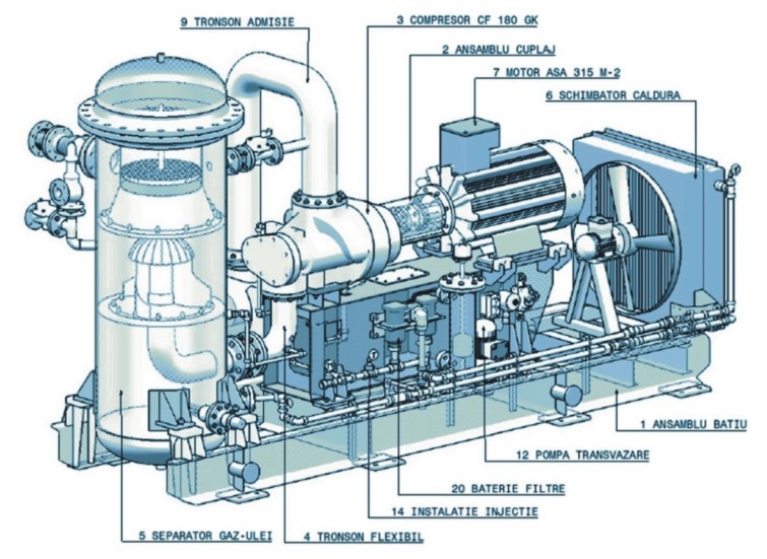

Ironline Compressions offers a

wide range of packages to our valued clients that are virtually unmatched by

others. We offer flexible solutions that specifically meet the requirements of

clients. The gas compression package that we offer comes with the benefit of

dealing with a professional and highly experienced team with extensive

resources and infrastructure. Here is what you need to know about our gas compression package.

Scaled rentals, on basis of

specific requirements

The rentals that we offer at

Ironline Compressions lends flexibility to our clients to utilize a combination

of our equipment and services in tandem with those of other providers. This

arrangement, offers clients the choice of opting for services which they feel

are more suitable, in addition to giving them better bottom lines in

operational costs. This permits clients to keep costs low, with the only

condition being the compatibility and integration of various components of

services.

End to end solutions

One of the more sought-after

solutions from our stable, this offers comprehensive all-round support to

client. This package, known as contract compression, includes comprehensive

maintenance across both scheduled and unscheduled categories which cater to the

urgent requirements of clients.

Superior technical support

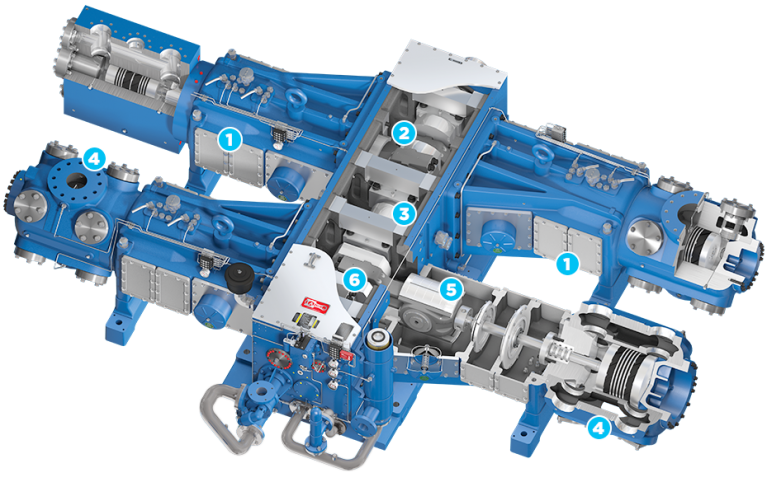

Minor and major overhauls are part

of the maintenance schedules and this greatly enhances the operational

efficiency of the equipment, in addition to preventing and pre-empting

equipment breakdowns. The complete packages that we offer comes loaded with the

advantages of our strong expertise and experience in the industry.

We are firm in our commitment to

our clients and it shows in the way we choose our equipment and resources. This

has the desired effect of delivering value to our clients with the best deals and

competitive pricing. You could also monetize your resources or assets through

different options which include sharing of surplus resources which will be

returned when required or sold out rightly.

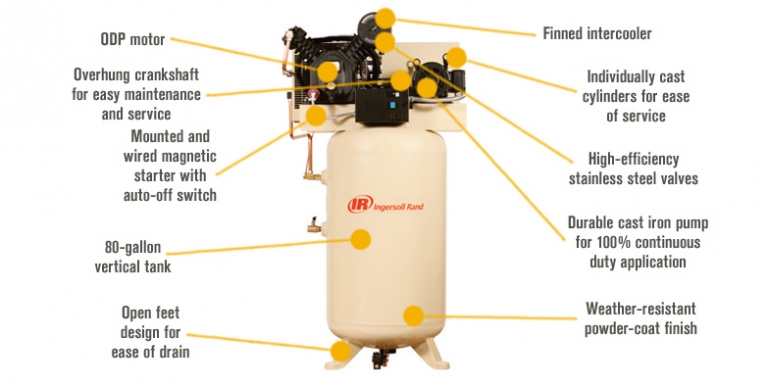

Our natural gas compression

package meets high standards, and helps you to keep your facility ready to meet

the challenges of market upheavals and disruptors. The demand for natural gas

and service is bound to only increase and a good and reliable package like ours

can make the difference to your operations.

Resource URL - https://www.ironline.com/gas-compression-package-need-know/